OhmegaPly® Embedded Resistor Technology

Introduction

The demand for high speed/high density printed circuit board (PCB) packaging compels the use of advanced packaging technologies, including embedded passives, in new circuit designs. OhmegaPly® has become the technology of choice in many critical circuit applications. It is used globally as a high volume, cost effective alternative to discrete SMT resistors.

There are numerous benefits in using OhmegaPly® including reduced surface EMI (Electrical Magnetic Interference), reduced inductive reactance, improved signal integrity of high speed, high frequency circuits and greater reliability resulting from the elimination of solder joints required for surface mounted resistors. More routing area is made available with elimination of the discrete SMT resistors and their interconnecting traces and vias.

Description

OhmegaPly resistors are thin film planar resistive elements that are part of the printed and etched circuitry on a standard PCB layer. OhmegaPly RCM® (Resistive Conductive Material) is comprised of a copper-conducting layer (copper foil) and a thin-film resistive alloy layer that has been deposited onto the “tooth” or matte side of the copper foil. The copper foils are single and double treat copper and are available in 1/2 oz (17 micron) and 1 oz (35 micron) weights.

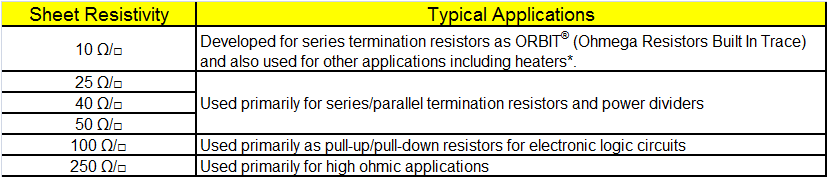

The OhmegaPly RCM® is available in a number of standard sheet resistivities expressed in ohms per square: 10 ohms/Sq, 25 ohms/Sq, 50 ohms/Sq, 100 ohms/Sq and 250 ohms/Sq.

Based on original equipment manufacturers (OEM) and PCB requirements, the OhmegaPly RCM® is laminated by independent laminators or PCB manufacturers to specific dielectric materials. It can be bonded to virtually any dielectric material and thickness currently being used by the Industry.

Design

Design of a specific resistor value follows thin film resistor design criteria – see the Ohmega Toolbox for more information. Sheet resistivity is the resistance in ohms per square and is a dimensionless number. The value of any specific resistor is determined by the ratio of the length of the resistor to its width multiplied by the sheet resistivity used. A simple example would be a 68 ohm value resistor that uses 25 ohm per square OhmegaPly. The total number of squares required would be 68 ohms divided by 25 ohms per square, or 2.72 squares. If the resistor width is designed to be 10 mils (0.010″) then the length of the resistor must be 10 mils x 2.72 squares or 27.2 mils (0.027″).

The OhmegaPly® laminate is processed by the PCB manufacturers the same way as other PCB laminates by a subtractive print and etch process. As with normal processing procedures, the board shop uses artwork or laser direct imaging to define geometric patterns that are imaged and etched to create individual resistors on either existing inner layers of a multilayer board or on the surface of a printed circuit board.

Reliability

OhmegaPly® embedded resistor technology has been used in numerous applications since the early 1970′s. Over the decades it has exhibited excellent long-term stability and reliability and has become the technology of choice in many critical circuit applications. In the millions of printed circuit boards, and trillions of component hours of use, OhmegaPly® has demonstrated absolute reliability. OhmegaPly® resistors in new designs are an application of a mature, well proven, technology.

Processing

Any PCB shop can process OhmegaPly®. No license or other fee is required. Since standard equipment, chemistries and process consumables are used there is minimal capital investment required by the board shop to process OhmegaPly®. Most electrical test equipment can be used with a software upgrade to enable resistor testing – see the Ohmega Toolbox for more information.

Cost/Benefit Analysis

The cost of using OhmegaPly® is dependent on the material price as supplied by Ohmega Technologies, Inc., the conversion cost that is applied to a printed circuit board by the board shop and any reduction in the overall board cost due to design enhancements. In addition to eliminating discrete surface mount resistors (SMT) and their assembly costs, PCB cost reduction is achieved by smaller board form factors, reduced layer counts, and the use of conventional PCB technologies rather than more expensive build-up and/or high density interconnect (HDI) technologies. In general, OhmegaPly® becomes economical to use – as a replacement for chip resistors – when the resistor density is approximately 5 to 6 resistors per square inch of board area.

Applications

OhmegaPly® is used in all areas of the electronics industry: military/aerospace, computer, telecommunications, consumer and medical electronics. Some of the applications include supercomputers, servers, graphic enhancement cards, workstations, application specific integrated circuit simulators (ASIC), automated test rquipment (ATE), active electronically scanned array radar systems (AESA), resistive cards (r-cards), probe cards, telecommunications switching cards, burn-in boards, heater elements, antennas, base stations, and cellular telephone modules. OhmegaPly® resistors are used as a direct replacement for discrete resistors. Some examples are as potentiometers, line terminators, pull-up/pull-down resistors, series and parallel terminating resistors, isolation resistors and as heater elements.

Typical Customer Questions

What is the OhmegaPly® resistive material made of?

OhmegaPly® is a true thin-film, Nickel-Phosphorous (NiP) alloy. In the manufacturing process, about 0.05 to 1.00 microns of the alloy is electro-deposited onto the rough, or tooth side, of electrodeposited copper foil.

What types of copper is it available on?

The copper foil is standard electrodeposited copper. Both single and double treat coppers of 0.5 oz and 1 oz are standard.

What types of dielectric materials are available?

OhmegaPly® is sold either in an unlaminated form call OhmegaPly® RCM (Resistor Conductor Material) or OhmegaPly® laminate form. Lamination is subcontracted to independent laminators and is available on most dielectric materials now offered in the industry.

What is Ohms per Square?

Ohms per square is a dimensionless square area of resistive material, the length and width of the resistor being of equal size, having an Ohmic value equal to the sheet resistivity of the resistive material deposited onto the copper surface. A 25 ohm sheet resistivity material would yield a 25 ohm resistor whether 1 mil wide by 1 mil long, or 1 inch wide by 1 inch long.

What resistive values are available?

OhmegaPly® is available in 10 ohm per square at ±3% tolerance and 25 ohm per square, 50 ohm per square and 100 ohm per square sheet resistivity at ±5% tolerance. A 250 ohm per square product is available at ±10% tolerance.

What size does the OhmegaPly® material come in?

The various sheet resistivities are manufactured reel to reel on equipment using two standard copper widths: 40″ and 45″. The lengths can vary, but the sheeted product is usually 51″ long to accommodate the laminators press size requirements. The RCM can be cut to custom sizes, if required.

What resistor values can be designed using OhmegaPly®?

Resistor values in the range of 5Ω to 50kΩ are achievable. The resistor values are a function of the available board area for routing the resistors, the resistor size, and the sheet resistivity used.

Resistor values outside the achievable range can and have been designed into circuit boards. Please contact us for more information.

Can I have multiple values of resistors on a layer?

Yes. The value of the resistor is determined by the ratio of the length of the resistor to its width multiplied by the sheet resistivity used. The number, and values, of the resistors used are a function of the dimensions as defined in the artwork.

Must you add a layer to a circuit board to use the OhmegaPly® resistors?

No. The resistors are almost always incorporated into an existing plane of circuitry. For parallel termination and pull-up applications, the resistors are usually placed on a voltage plane. For series termination the resistors are usually placed on a signal plane. The resistors can be used on an internal layer of the circuit board, or can be used on a surface layer.

Can I use more than 1 layer of the resistive material in the circuit board?

Yes. There are numerous applications which now use more than one layer. There is no maximum number of layers that can be used within a circuit board.

What is the tolerance of the final resistors?

The nominal cumulative resistor tolerance is a function of resistor size, number of resistors on the board and the size of the board itself. Normally, an 8% to 15% tolerance is achievable for resistors which are multiple squares and a minimum of 20 mils wide. Most applications for termination or pull-up resistors can accommodate this tolerance range. For partial square resistors or designs using 100 ohm per square material with multiple resistor values and shapes on a layer, a 15-20% tolerance is what most board shops request.

What is the minimum size the resistor can be made?

The size of the resistor is only limited by the board shop’s ability to etch accurate lines. As a rule of thumb, the larger the resistor, the better. Most resistor line widths are between 5 and 20 mils, with 10 mils being the most common. There have been resistor applications with line widths less than 5 mils, but currently these are the exception rather than the rule.

What kind of power rating do the resistors have?

The amount of power that can be applied to the resistor is limited by the size of the resistor, the thermal management of the heat generated from the resistor, and the type of dielectric material used. A typical power rating would be about 1/8 watt, but this can be increased with the use of heat sinks and higher temperature laminate materials.

When does it become cost effective to use OhmegaPly®?

The use of OhmegaPly® provides both design and cost benefits. A number of cost savings are realized by eliminating discrete resistors, including the cost of the discretes and their accompanying direct and overhead costs of inventory, assembly and rework. These costs will vary from customer to customer. The greater the resistor density, the greater the cost savings.

For a pure “retrofit” design which replaces discrete resistors with OhmegaPly® and with no design enhancements or improvements, the cost benefits usually begin if the resistor density is approximately 5 to 6 resistors per square inch of board. For applications where there are design enhancements and/or board improvements (e.g. double sided SMT being designed into a single sided SMT board), the cost benefits can begin at a lower resistor density.

How much more does a finished circuit board cost with OhmegaPly®?

For a typical board size of 18″ x 24″ (3 square feet) a board shop would add about $200 for low volume applications and about $90 to $100 for high volume applications to the price of the board. This adds between $0.21 to $0.46 per square inch to the finished board depending on the board volume and the technical difficulty associated with the board manufacture.

The added cost would be offset by the elimination of the discrete resistor costs and the costs of assembly, rework and inventory as well as the design and electrical enhancements to the finished circuit board.

Is OhmegaPly® a “green” technology that complies with US environmental regulatory requirements and the EU Directives?

OhmegaPly® Laminates formulated for lead-free assembly is available. It is RoHS and REACH compliant and UL Approved. Ohmega Technologies is UL approved as a “Repackager of Laminates.” Certificates of Compliance and MSDS are available upon request.

Who has used OhmegaPly®?

OhmegaPly® has been used in numerous applications for five decades by a number of world class OEM’s (original equipment manufacturers). Some of those include:

- Advance Fibre

- Agilent

- Alcatel Bell

- Apple

- Boeing

- BAE

- Canon

- Control Data

- Cray Research

- Data General

- Fujitsu

- Hewlett Packard

- Honeywell

- IBM

- Loral Defense

- Loral Space

- Lucent

- Mitsubishi

- Motorola

- NCR

- Nikon

- Nokia

- Northrop Grumman

- Pentax

- Raytheon

- Rockwell

- Sun Microsystems

- Tektronix

- TRW

- Unisys

- Wang

Please contact us with any questions you may have and we’ll be delighted to assist you.